Home - EV charging connectors 99.9% copper terminals CCS1 CCS2 European Standard

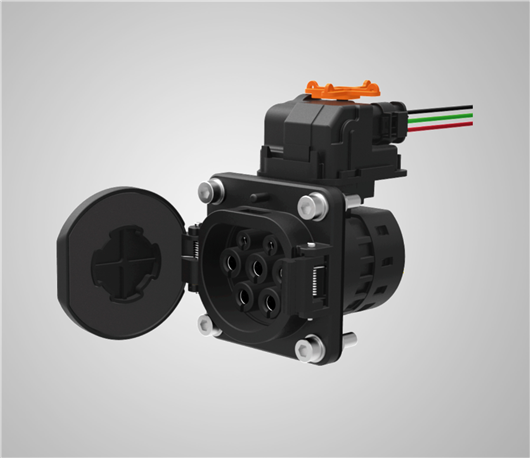

EV charging connectors 99.9% copper terminals CCS1 CCS2 European Standard

Detailed specification for copper terminals used in EV charging connectors requires addressing various technical, material, and compliance aspects.

1.Specification for EV Charging connectors Copper Terminals

General Overview

This specification outlines the requirements for copper terminals to be used in electric vehicle (EV) charging stations. These terminals are critical components ensuring efficient and safe electrical connections between the charging station and the vehicle.

2. Technical Requirements

2.1 Electrical Characteristics

-Current Rating: Terminals must support continuous current ratings of up to 200A.

– Voltage Rating: Terminals must be rated for operating voltages up to 1000V DC.

– Contact Resistance: Maximum contact resistance should not exceed 0.5 mΩ to ensure minimal power loss and heat generation.

-Temperature Rating: The terminals must operate efficiently in temperatures ranging from -40°C to +125°C.

2.2 Mechanical Characteristics

Material: High conductivity copper with a minimum purity of 99.9% to ensure optimal electrical performance.

Plating: Terminals should be tin-plated or silver-plated to enhance corrosion resistance and electrical conductivity.

Tensile Strength: Terminals must have a tensile strength of at least 210 MPa.

Connector Design: Terminals should be compatible with standard crimping tools and techniques, ensuring secure and reliable connections.

2.3 Physical Dimensions

Conductor Size Compatibility: Terminals must accommodate conductor sizes ranging from 4 AWG to 4/0 AWG.

Terminal Thickness: Thickness should be sufficient to withstand mechanical stress without deformation, typically 1.5 mm to 3 mm, depending on the terminal size.

3. Environmental and Durability Requirements

3.1 Corrosion Resistance

– Terminals must pass a salt spray test for a minimum of 500 hours per ASTM B117 to ensure long-term durability in various environmental conditions.

3.2 Vibration and Shock Resistance

– Terminals should comply with IEC 60068-2-6 and IEC 60068-2-27 standards for vibration and shock resistance to ensure reliability in high-vibration environments.

3.3 Thermal Cycling

– Terminals must withstand thermal cycling tests per IEC 60068-2-14, simulating temperature fluctuations that occur during charging and discharging cycles.

4. Compliance and Standards

4.1 Industry Standards

– Terminals must comply with relevant industry standards such as IEC 62196, IEC 62893, and UL 486A/B for safety and performance.

– RoHS (Restriction of Hazardous Substances) compliance is mandatory, ensuring that materials used do not contain prohibited substances.

4.2 Certification

– Terminals must be certified by recognized testing laboratories (e.g., UL, TÜV) to verify compliance with safety and performance standards.

5. Testing and Quality Assurance

5.1 Inspection and Testing

– Each batch of terminals must undergo rigorous quality control tests, including dimensional verification, tensile strength testing, contact resistance measurement, and visual inspection for defects.

– Manufacturers must provide test reports and certificates of conformity for each batch.

5.2 Quality Management System

– The manufacturer should maintain an ISO 9001 certified quality management system to ensure consistent product quality and continuous improvement.

6. Packaging and Labeling

6.1 Packaging

– Terminals should be packaged in a way that prevents damage during transit. Packaging must protect against moisture, dust, and mechanical impacts.

6.2 Labeling

– Each package must be clearly labeled with the product type, specifications, batch number, manufacturing date, and handling instructions.

7. Warranty and Support

7.1 Warranty

– The manufacturer should offer a minimum warranty period of 5 years from the date of installation, covering defects in materials and workmanship.

7.2 Technical Support

– The manufacturer should provide technical support for installation, troubleshooting, and maintenance.

This specification ensures that the copper terminals used in EV charging stations meet high standards for performance, safety, and durability.