Ⅰ. DC gun insertion and extraction force solution

According to GBT 20234.1-2015 “Electric Vehicle Conductive Charging Connection Device Part 1: General Requirements” 6.4 Insertion and extraction force requirements, DC charging gun insertion and extraction force due to less than 140 N. However, the customer in the charging position of the high or low use of the occasions, the insertion and extraction of the more laborious, especially the lady to operate up is very difficult, the third paragraph of the Division Company’s DC charging gun on the structure of the optimisation, so that the insertion and extraction of the more soft and smooth. Our third DC charging gun has optimised its structure to make the plugging and unplugging softer and smoother, the plugging and unplugging force is less than 120N.

| Charge Gun Brands | Rechargeable Holder Brands | Insertion force/withdrawal force test (N) | ||||

| 1 | 2 | 3 | 4 | 5 | ||

| Wall’s third DC charging gun | Brand A DC Block | 118/112 | 117/98 | 103/91 | 109/99 | 113/105 |

| Brand B DC Block | 98/78 | 101/85 | 93/76 | 100/91 | 95/74 | |

| Wall DC Block | 110/106 | 103/95 | 105/87 | 112/101 | 95/85 | |

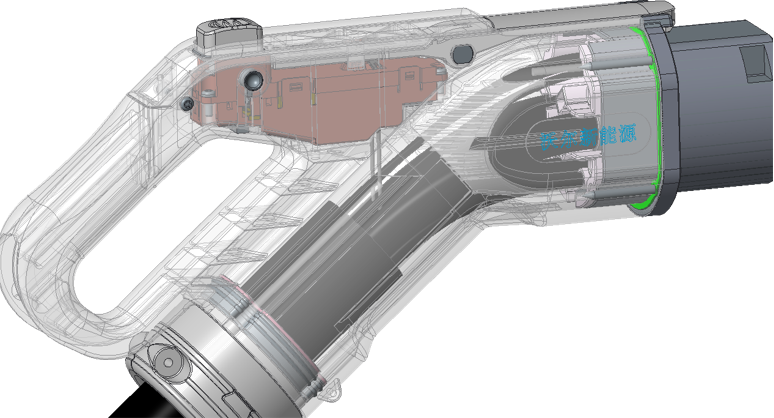

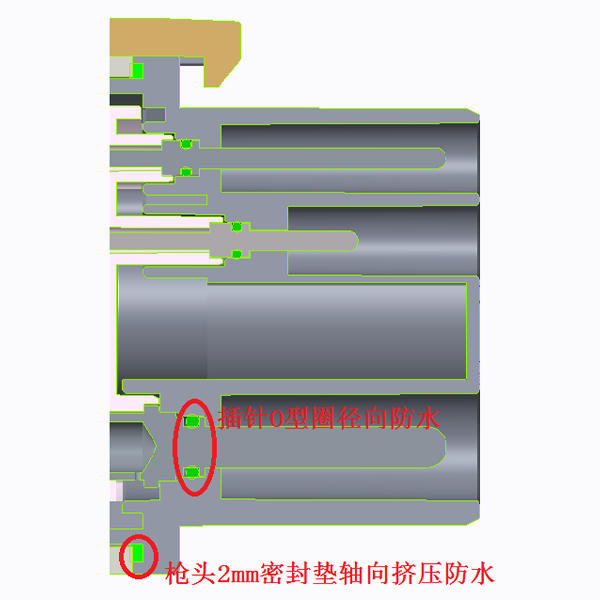

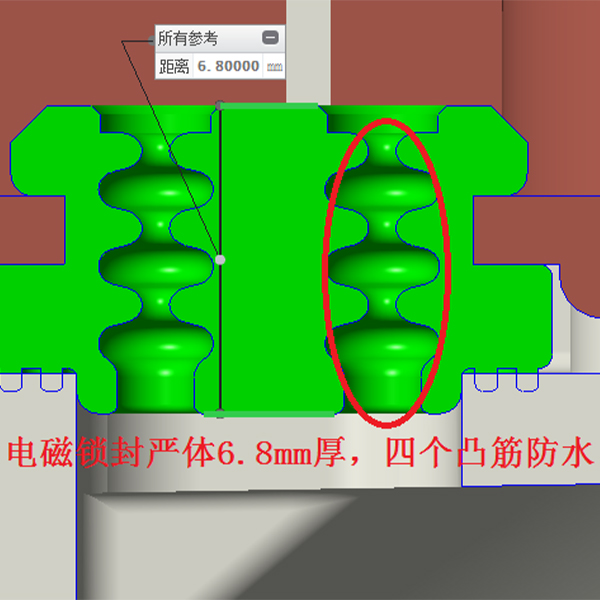

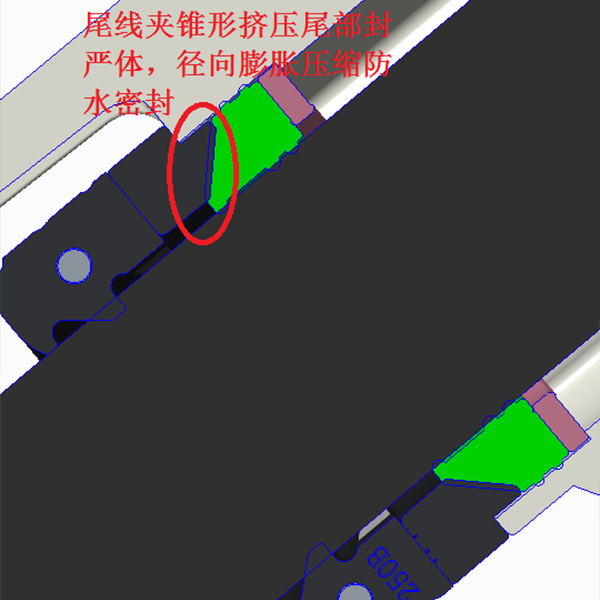

Ⅱ. Waterproofing solutions for DC guns

According to GBT 20234.1-2015 “Electric Vehicle Conductive Charging Connection Device Part 1: General Requirements” 6.9 protection level requirements, DC charging gun should reach IP54 protection level. However, in the process of long-term application, customers encountered the risk and hidden danger of water leakage of the charging gun in extreme situations such as continuous rainstorms and the charging gun falling into puddles, etab. In this regard, after in-depth tracking and research, our company has developed the third model of DC charging gun that can be individually sealed and waterproofed with waterproof grade up to IP67, which is higher than that required by the national standard.

Ⅲ. DC gun emergency unlocking solution

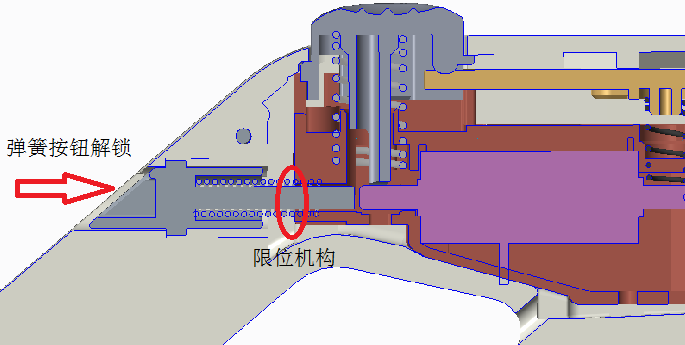

Electromagnetic lock emergency unlocking on the market has been a frequent customer complaints, the industry’s most common way of emergency unlocking is to use a special unlocking key to toggle the electromagnetic lock pusher to achieve unlocking, this way there are three aspects of the shortcomings: 1. unlocking the key hangs on the gun unattractive and easy to lose; 2. unlocking holes are easy to be blocked by mud, dirt and fly dust, etc.; 3. unlocking the use of personnel unfamiliar with the operating essentials, it’s easy to Unlock the hole in the point of components to poke bad. At present, there is a pull rope unlocking method on the market, although it solves the above problems, but because of the risk of breakage of the pull rope in the process of long-term use, once the pull rope is broken, the charging gun will not be able to be unlocked. After in-depth research, our company introduced the spring button unlocking method on the third DC charging gun, which is highly reliable and easy to unlock.

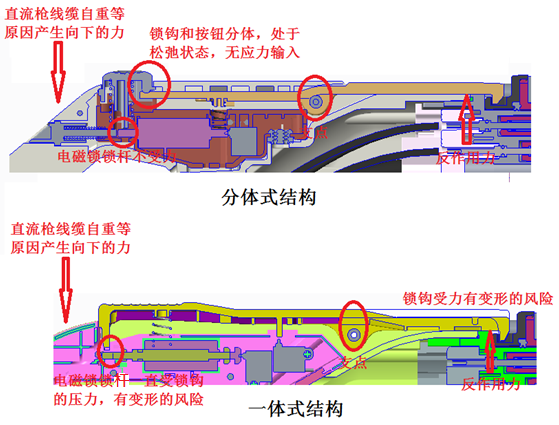

Ⅳ. DC Gun Lock Hook Deformation Solution

The most common DC charging gun locking hook on the market is the one-piece locking hook, the locking hook structure is simple, but in the charging process, due to the charging gun and cable weight, such as the seesaw principle, the locking hook and the electromagnetic lock push rod will always be stressed, long-term use of the process of locking hooks and electromagnetic lock locking rod deformation risk. In addition, there is no cushion for the one-piece locking hook, if the operator forgets to press the locking hook in the process of insertion and closure, it will lead to the interference between the locking hook and the charging seat, resulting in the deformation of the locking hook. After in-depth research, our company has optimised the third DC gun locking hook into a split structure to solve the above hidden problems, and it can be smoothly inserted and closed without pressing the locking hook, without damaging the locking hook.

V. DC charging connector temperature rise heat solution

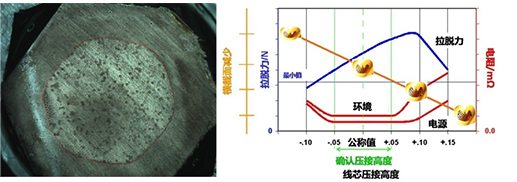

The problem of DC charging gun temperature rise and heating is common in the market, our company according to customer feedback and actual application, after in-depth research, in the third DC charging gun to carry out the following optimisation: 1.DC+ and DC- terminal compression line cup mouth lengthening, our compression line cup mouth than the market compression line cup mouth generally longer than 4mm, in addition to our company also on the cable compression ratio for in-depth study; 2. Wall third DC gun temperature sensor is fixed in the cable stripping position, with heat shrink tubing to wrap the terminals, cable and thermistor together all together, higher sensitivity; 3. Wal third DC gun terminal fixing surface lengthening, in addition to radial screw fixing to ensure that the terminal will not be affected by cable bending, to ensure that the position of the terminal degree and coaxiality, reduce temperature rise.

Relationship between crimp height and mechanical/electrical properties

With the increase of crimping height, the pull-off force first increases and then decreases, the resistance first decreases and then increases, the pull-off force qualified at the same time the resistance of the smallest area that is the range of crimping height.

VI. DC Gun Charging Matching Compatibility Solution

The market for new energy vehicle brands and models, many brands of charging guns in the early stage of the actual application of the process of interference, Wall third DC charging gun to learn from experience, optimise the size of the shape, and can be matched with a variety of brands of electric vehicles on the market charging.

1. The height dimension from the top of the locking hook to the top of the vehicle plug insulator is ≤18mm, to avoid the locking hook dimension is too high to interfere with the vehicle charging port; 2. The angle of the gun body is ≥135° to avoid interference with the vehicle charging port because the angle of the gun body is too small; 3. The distance from the button to the head is ≥150mm, to avoid interference with the charging port of the vehicle because the button is too close to the head. 4. The transverse left and right widths of the gun case are ≤76mm, avoiding the interference between the gun case and the vehicle charging seat latch.